Main Operations of MIJ Labo

To address challenges in the grading of beef carcasses, we engage in the following activities:

- Development and sales of carcass imaging cameras (for domestic and international markets)

- Image analysis

- Provision of cloud services for data storage (research and development of a carcass database)

- Joint research

- Consulting

Development and Sales of Carcass Imaging Cameras (Domestic/International)

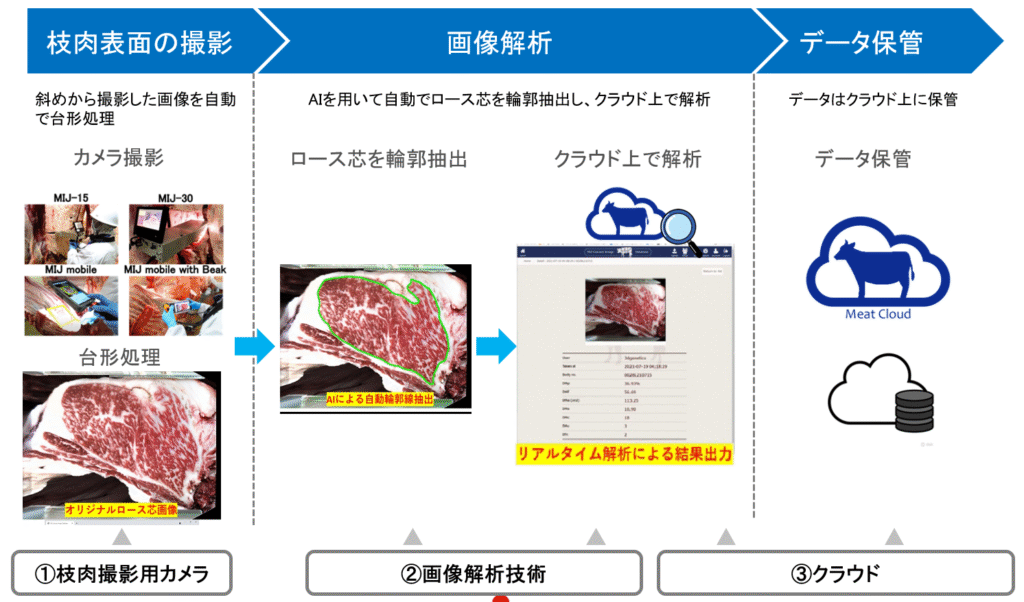

We developed the world’s first compact and lightweight camera specifically for beef carcass imaging. Unlike conventional mirror-type cameras, our system enables real-time analysis.

MIJ Mobile (Domestic / International)

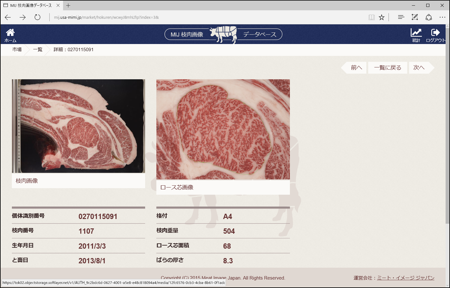

Using a barcode reader, the carcass identification number is scanned, and the cross-section of the carcass is captured.

Capable of capturing images of over 200 carcasses per hour

Instantly performs trapezoid correction, brightness uniformity adjustment, 90-degree rotation, and ribeye area contour extraction

[Other Lineup]

We will recommend the most suitable model based on the cross-sectional size of the carcass.

- MIJ-15K (For domestic use)

- MIJ-30K (For overseas use)

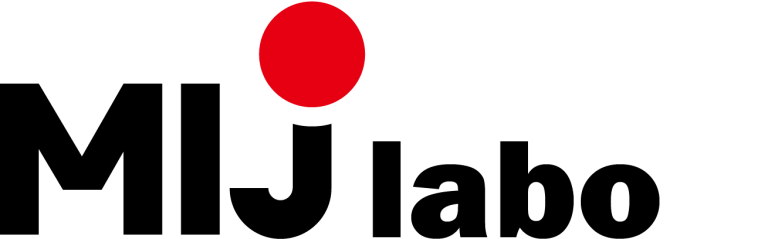

Provision of Cloud Services for Image Analysis and Data Storage (Research and Development of a Carcass Database)

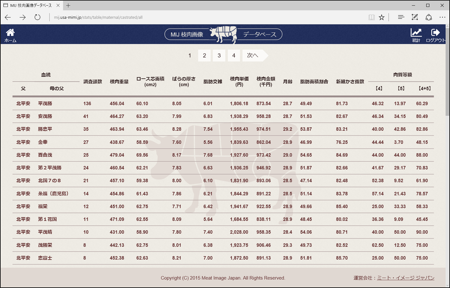

Captured data is linked to the individual identification number, and ribeye area contours are automatically extracted. More than 10 items—including ribeye area, BMS (Beef Marbling Standard), BCS (Beef Color Standard), and fat content—are analyzed, enabling accurate evaluations and the collection of valuable data for genetic improvement.

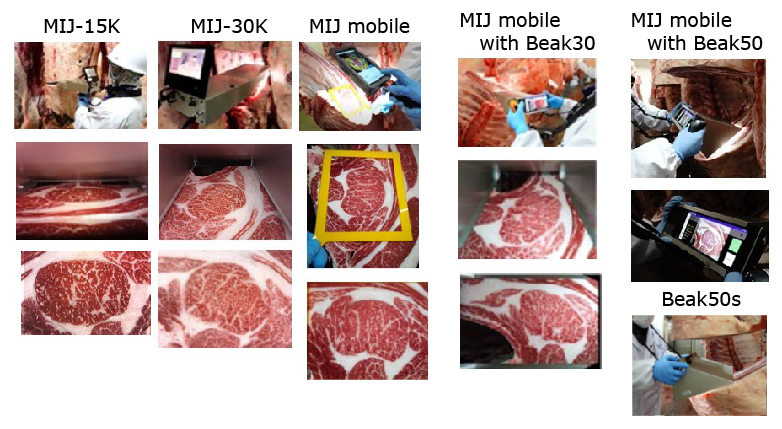

Carcass Database

Accessible 24/7/365 via the cloud, both domestically and internationally. Users log in with personal or organizational ID/password credentials. Data is securely managed in a protected environment.

Joint Research & Consulting

Here are some of the research and consulting projects currently underway (as of July 2025):

Research Using a Component Analyzer Equipped with a Near-Infrared Spectroscopy Sensor Module

Using an ultra-compact sensor (25×25×17mm, 15g) in conjunction with MIJ Mobile, we are exploring the feasibility of measuring the following components:

- Fine marbling analysis (optical)

- Fatty acid composition (MUFA, oleic acid)

- Fat melting point

- Glutamic acid and inosinic acid

- Moisture content

- Lactones

AI-Based Meat Quality Estimation from Live Cattle at Slaughter (BMS Prediction)

Patents acquired (e.g., similar image suggestion, image extraction from ultrasound video, analysis algorithms)

- If meat quality is underdeveloped → Improve feeding methods to enhance quality and increase price per unit!

- If meat quality is sufficient → Ship earlier to reduce feeding costs! Increase number of shipments by improving livestock turnover rate!